Introduction

NIPLATE® Coatings

NIPLATE® coatings identify a family of electroless nickel plating treatments developed to meet different requirements in terms of corrosion resistance, wear, friction, and specific surface functionalities.

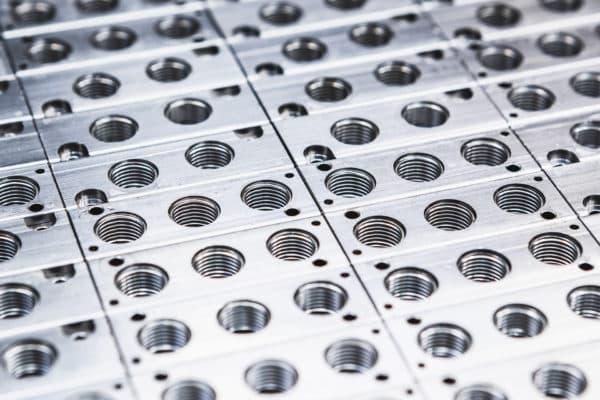

All NIPLATE® coatings share the typical characteristics of electroless nickel plating (uniform thickness, no edge build-up, and excellent adhesion to the base material) but differ significantly in alloy composition, deposit structure, and the possible presence of co-deposited particles or dedicated functional optimizations.

Understanding these differences is essential to select the most suitable treatment for the application and to specify it correctly on the drawing.

Traditional NIPLATE® coatings (Ni–P)

In the electroless nickel plating process, the action of the reducing agent leads to the deposition of a nickel–phosphorus (Ni–P) alloy. Phosphorus content is one of the most relevant parameters because it directly affects the microstructure of the coating and, consequently, its mechanical, chemical, and magnetic properties.

Depending on the percentage of phosphorus incorporated in the layer, traditional NIPLATE® coatings are divided into:

- medium-phosphorus electroless nickel (5–9% P)

- high-phosphorus electroless nickel (10–13% P)

Both types can be applied to a wide range of metal alloys and allow uniform thicknesses from a few microns up to several tens of microns, depending on the required performance.

NIPLATE® 600 – Medium-phosphorus electroless nickel

NIPLATE® 600 – Medium Phosphorus Electroless Nickel Plating

Wear resistance | Corrosion resistance | ISO 4527 NiP(7)

NIPLATE® 600 is a medium phosphorus (5–9% in P) electroless nickel plating coating. It is the most widely used of the NIPLATE® coatings thanks to its good wear resistance, corrosion resistance, and favorable balance between technical performance and cost-effectiveness.

NIPLATE® 600 is recommended when wear resistance is the main requirement, particularly in the presence of repeated mechanical sliding and tribological stresses.

Its structure and good response to hardening heat treatments make it possible to obtain hard, wear-resistant surfaces, while maintaining good corrosion protection of the base material.

NIPLATE® 500 – High-phosphorus electroless nickel

NIPLATE® 500 – High Phosphorus Electroless Nickel Plating

High corrosion resistance | ISO 4527 NiP(11)

NIPLATE® 500 is a high-phosphorus (10–13% in P) electroless nickel plating coating, selected when corrosion and chemical resistance are the primary requirement.

NIPLATE® 500, thanks to its high phosphorus content, has a predominantly amorphous structure and very low porosity, even at limited thicknesses.

It is particularly suitable for aggressive environments or applications where protection of the base material is critical.

NIPLATE® eXtreme – Electroless nickel for aluminum alloys

NIPLATE® eXtreme Electroless nickel plating

Optimized corrosion resistance for aluminum

NIPLATE® eXtreme is an electroless nickel coating specifically developed to increase corrosion resistance on aluminum alloys.

NIPLATE® eXtreme is designed for applications on aluminum alloys, where high corrosion reliability is required together with the uniformity typical of electroless nickel plating.

Functional and composite NIPLATE® coatings

Alongside traditional Ni–P coatings, the NIPLATE® range includes treatments developed for specific functional requirements, in which the Ni–P matrix is optimized or integrated with solid particles to modify surface behavior.

NIPLATE® 500 PTFE – Electroless nickel with PTFE

NIPLATE® 500 PTFE Electroless Nickel Plating with PTFE

Self-lubricating | Non-stick

NIPLATE® 500 PTFE is a composite high-phosphorus electroless nickel coating containing PTFE particles. It features a very low coefficient of friction and non-stick properties.

NIPLATE® 500 PTFE is recommended when it is necessary to reduce friction or avoid the use of lubricants, while maintaining uniform thickness and good corrosion resistance.

NIPLATE® 600 SiC – Electroless nickel with silicon carbide

NIPLATE® 600 SiC Electroless Nickel Plating with SiC

Extreme wear resistance

NIPLATE® 600 SiC is a composite coating with silicon carbide (SiC) particles, designed for applications subject to severe abrasive wear.

NIPLATE® 600 SiC is used when wear is the limiting factor in component service life, thanks to the presence of ceramic particles with extremely high hardness.

NIPLATE® LINK – Electroless nickel for electrical and solderable components

NIPLATE® LINK – Electroless Nickel for Busbars and Solderable Components

Solderable surface | Tarnish resistance | E-mobility

NIPLATE® LINK is a proprietary electroless nickel plating treatment developed for copper busbars, connectors, and electrical components intended for soldering and brazing, with high long-term surface stability.

NIPLATE® LINK is a functional treatment specifically intended for electrical and interconnection components, such as copper busbars, connectors, and parts intended for soldering or brazing.

It was developed to ensure a solderable, tarnish-resistant, and long-term stable surface, reducing the risk of surface oxidation that could compromise joint quality and reliability.

Thanks to the coating’s high thickness uniformity and excellent adhesion, NIPLATE® LINK improves connection reliability in power distribution systems and reduces failures due to joint defects, even with complex geometries.

The treatment is particularly suitable for e-mobility applications, such as busbars for electric vehicles, inverters, battery packs, and power converters, where connection durability and long-term stability are essential requirements.

Its good corrosion resistance also enables use in water-cooling circuits and in humid or saline environments.

From a process standpoint, NIPLATE® LINK is a repeatable industrial solution, cost-effective and free of precious metals, developed in-house by Micron and covered by a filed patent application, ensuring uniqueness and competitive advantage.

Coating selection criteria

Selecting the most suitable NIPLATE® coating must always take the overall application into account, considering:

- base material and its metallurgical quality;

- type of stress (wear, corrosion, friction, solderability);

- operating environment;

- available thickness and dimensional tolerances;

- need for post-deposition heat treatments.

The following sections of the guide examine these aspects individually, providing technical criteria to correctly specify the treatment and achieve reliable, repeatable performance over time.