Electroless plating properties

Coefficient of friction and non-stick properties

The coefficient of friction is one of the most relevant functional properties in the design of components subject to relative sliding, repeated contact, or high loads. Electroless nickel plating makes it possible to control and modify the tribological behavior of surfaces, reducing friction, preventing seizing phenomena, and improving in-service reliability, both under lubricated and dry conditions.

The coefficient of friction value depends not only on the coating, but also on the counterface material, surface condition, load conditions, sliding speed, and the presence or absence of lubrication. The values reported below are indicative and refer to controlled test conditions.

NIPLATE® 500, NIPLATE® eXtreme and NIPLATE® 600

The NIPLATE® 500, NIPLATE® eXtreme, and NIPLATE® 600 coatings have a coefficient of friction that is generally lower than traditional metal-to-metal pairings used in mechanics. This characteristic helps reduce adhesive wear and prevent seizing phenomena, even under high surface loads.

In dry sliding conditions, the coefficient of dynamic friction of these coatings typically ranges from 0.4 to 0.6, depending on the counterface material and operating conditions. These values make these coatings suitable for applications where a good balance between wear resistance, stability of tribological behavior, and coating robustness is required.

NIPLATE® 600 SiC

The NIPLATE® 600 SiC is a composite coating characterized by the presence of silicon carbide (SiC) particles dispersed in the electroless nickel matrix. The inclusion of an ultra-hard ceramic phase significantly increases resistance to abrasive wear, but results in a higher coefficient of friction compared to the non-composite NIPLATE® 600.

In dry sliding conditions, the coefficient of dynamic friction of NIPLATE® 600 SiC generally varies between 0.5 and 0.8, due to the mechanical interference of the SiC particles with the counterface surface. This behavior is consistent with the intended use of the coating, which prioritizes durability under severe wear conditions over friction minimization.

NIPLATE® 500 PTFE

The NIPLATE® 500 PTFE coating (see NIPLATE® coatings) is a high-phosphorus electroless nickel matrix composite coating containing PTFE particles, typically in a concentration between 25 and 35% by volume. PTFE is a polymer characterized by excellent non-stick and self-lubricating properties, which give the coating a distinctive tribological behavior.

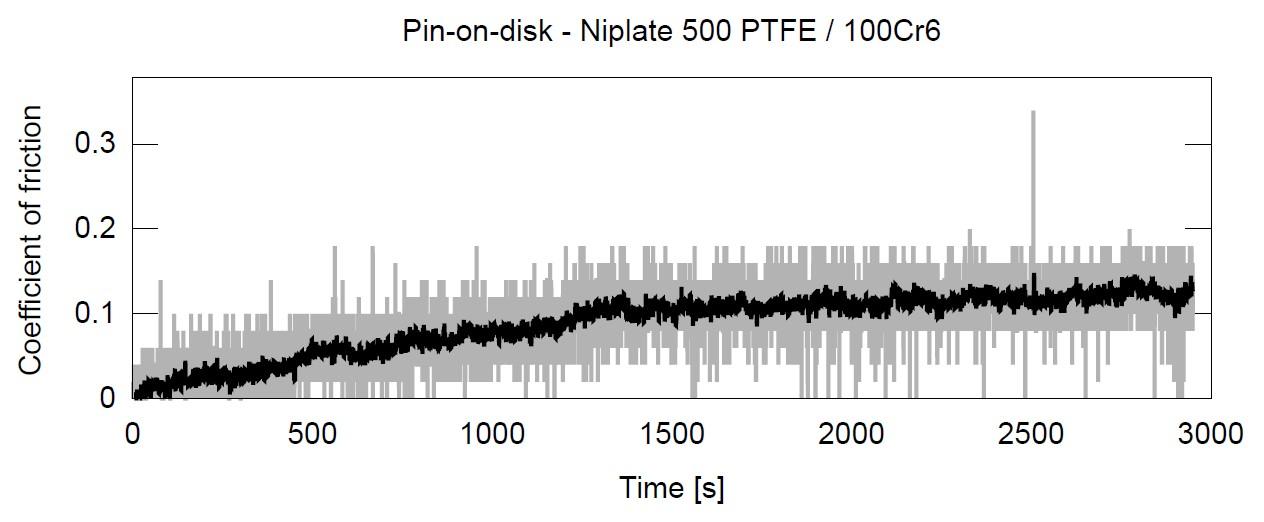

This coating combines the typical properties of electroless nickel plating, such as uniform thickness, adhesion to the base metal, and wear resistance, with a marked reduction in surface friction. In the absence of lubrication, the coefficient of friction of NIPLATE® 500 PTFE is typically about 0.10, significantly lower than traditional metallic coatings.

The presence of PTFE also provides a pronounced non-stick property, making the coating suitable for applications where it is necessary to prevent sticking, buildup, or encrustations, such as on heat exchangers or components subject to limescale deposits.

The following graph shows the results of a coefficient of dynamic friction measurement test using a ball-on-disk test against 100Cr6 steel.